Stockholm

As you can see from the dates we have spent quite a long time in Stockholm, 6 nights in fact, a long stay by our normal standards. It has proven to be a good base for some Africa prep, a bit of sight seeing and some vehicle work/repairs.

We made three trips into Stockholm Central from our campground and have done a few of the standard tourist things, The Vasa Museum, the Gamla Stan (old town), the Nobel Museum and yesterday a fabulous photographic exhibition.

The Vasa was really quite interesting. The size of the ship was more than a bit impressive but the part of its story that surprised me most was that it sank in the harbor on its maiden voyage - seems that designed faults are not just a feature of modern engineering. More generally Stockholm was a pleasant city just to walk around and do some people watching.

But in truth our stay in Stockholm has been more about prep for Africa and vehicle repairs. On the Africa front we got some more "expedition" clothing so that we are suitably attired on our safari and Nina set about applying a high-tech solution to her clothes in the hope that this will help ward off the insects.

The news on the vehicle repair front is pretty good, I think. Lets start with the leaking air conditioner.

The Air Conditioner

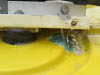

After some extensive inspection I diagnosed the problem as poor installation. On the roof of the truck's cab there is a circular drain channel designed to move water away from whatever one decides to install inside the channel. The air conditioner unit, mounts on 4 rubber feet on top of the roof and the bolts pass through the rubber feet and through the roof to hold the unit in place. In addition a hole about 10" square needs to be cut into the roof for the main part of the unit to protrude into the cab. The 10" hole fits completely inside the circular channel but the rubber feet are too widely spaced.

It is pretty clear after some inspection that the technician that installed the unit positioned the 10" hole through the roof without giving thought to where that would place the rubber feet and their associated bolt holes. The positioning turned out to be particularly poor as the rear two feet and bolt holes lined up perfectly with the edge of the drain channel. Thus the two rear bolt holes passed through the sloping edge of the channel rather than a flat surface. Now I would have thought it obvious at this point that those rear rubber feet would never adequately seal against the roof surface with the hole in that position. But the technician did not seemed disturbed by this, instead a piece of 1"x1/4"x 12" plastic was placed in the channel to give the rubber feet an approximately flat surface to stand on and then the whole thing was swamped in silicon sealant.

Well of course that worked for a while, but time and vibration eventually did their work and the hole on the driver's side of the truck started leaking.

I guess the lesson from this is that silicon is no substitute for competence.

So the correction I have made is the obvious one of moving those rubber feet to a place where they stand on a nice flat surface that can be adequately sealed - the solution that should have been employed in the original installation. Oh, and of course I also had to patch up the original holes. I hope the epoxy I used for that will last until a more permanent solution can be found in Gaggenau.

The whole exercise was more than a bit frustrating as the cabs head liner had to come down and all the work on the roof had to be done from a precarious position on a ladder.

But the more frustrating thing is the poor quality of the installation work. This is the third instance of poor workmanship associated with the AirCon. We have previously had two situations where the unit has stopped working because poorly routed hoses have developed leaks from abrasion. Plus, in May of this year we took the truck back to ThermoKing complaining about this water leak and all they did was add more silicon.

The water leak under the kitchen sink

Moving on to our long term "water under the sink" problem.

The evidence has been mounting that the culprit is the hot water storage tank and that it is leaking somewhere.

For most of our time in Stockholm we have had the water pump turned on (so that the system is under pressure, about 45 psi) but we did not heat the water with the engine or the Thermo90 heater. Under those circumstances there is no leak that we can find. The floor both under and in front of the kitchen sink remained dry.

As an experiment a couple of days ago I turned on the Thermo90 heater and ran it for 20 minutes, enough time to bring the water in the hot water storage tank up to 180°F and more significantly increase the pressure in the tank. Suddenly we have water on the floor again.

For me that was enough evidence that the leak is in the hot water storage tank and a new one is required (or this one fixed). So yesterday I set about disconnecting and removing the tank from under the sink.

Once the tank was out, its cover removed, and could be inspected two things were of interest. The first is that repair of the existing tank is not practical as the thing is covered with insulation that could not be removed and then replaced. Secondly there was evidence of water inside the tank cover.

So now we just get and install a new one and hope that the leak is no longer with us.